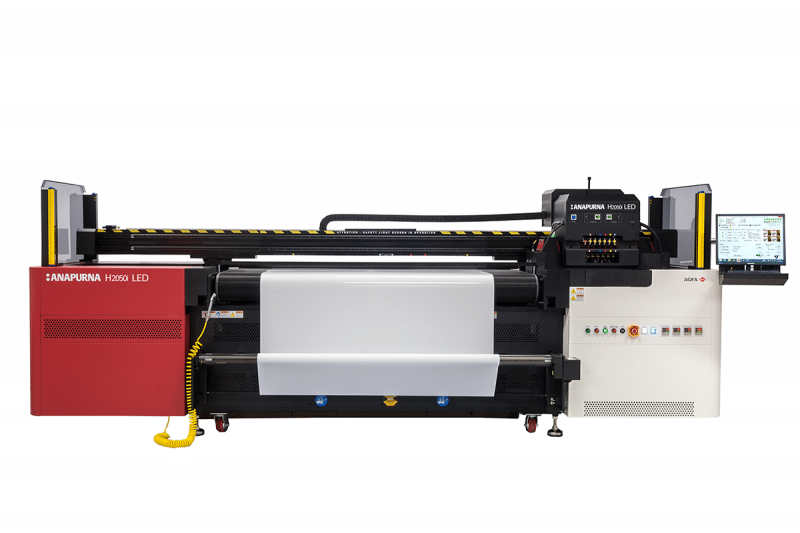

Hybrid Anapurna LED Series

High-speed 4/6-color + white hybrid UV LED-curable inkjet system with a printing width from 1.65 to 3.2 m for indoor and outdoor applications.

The wide-format hybrid Anapurna LED series is a perfect fit for sign shops, digital printers, photo labs and mid-size graphic screen printers that want to combine board and roll-to-roll print jobs.

The engines print at a width up to 3.2 m and combine high quality with high productivity for outdoor and indoor, rigid and flexible wide-format jobs. The white ink function creates possibilities for printing on transparent material for backlit applications or for printing white as a spot color. Go for the optional automatic board feeder to increase your productivity even more.

The hybrid Anapurna LEDs are fitted with air-cooled UV LED lights that save you energy, costs and time. Due to their minimal energy output, these LED lights are ideal for thin heat-sensitive materials. They also lead to faster operations as they can be switched on and off instantaneously.

Key benefit

- High-quality printing on a wide range of uncoated rigid media as well as on roll media

- Robust industrial engineered concept fit for sustained higher workloads

- UV LED lamps that enable printing on thermally sensitive materials and save costs, time and the environment

- High productivity—enhanced even more by multiple board printing and/or automatic board feeding

- UV LED ink for fast drying, material versatility and a very wide color gamut

- Printing pre-, sandwich and post-white in one run

- Thin Ink Layer technology for the lowest ink consumption in the market

- Powered by Asanti workflow software

Watch the movie

Brochures

- Anapurna H1650i LED (English)

- Anapurna H1650i LED (French)

- Anapurna H1650i LED (German)

- Anapurna H1650i LED (Italian)

- Anapurna H1650i LED (Portuguese)

- Anapurna H1650i LED (Spanish)

- Anapurna H LED series(English)

- Anapurna H LED series(German)

- Anapurna H LED series(French)

- Anapurna H LED series(Italian)

- Anapurna H LED series(Portuguese)

- Anapurna H LED series(Spanish)

Features

Solid design for great accuracy

Thanks to a reinforced belt drive and shuttle beam, the hybrid Anapurna printers bring a highly accurate dot positioning and thus excellent image quality, which is further enhanced by the gradient and multi-layer functionality. The eight 12 picolitre heads guarantee printing of good solids, fine text reproduction of up to 4 pt, good tonal rendering and low ink consumption.

UV LED lamps that save time, costs and the environment

The hybrid Anapurna printers are fitted with air-cooled 16 Watt/cm² UV LED lamps, which results in a number of unique advantages related to generating extra business, cost savings and environmental friendliness. These include a wider applications scope, higher productivity and less power consumption.

Read more about the unique advantages of LED technology.

Latest generation of fast-firing print heads

Incorporating the latest generation of fast-firing print heads, the hybrid Anapurna’s offer an impressive throughput. They enable you to maintain a high print production on all substrates, satisfying even your most demanding customers.

Multiple board and automatic board printing

The Anapurna H2050i and H2500i can have an automatic board feeder added in order to increase productivity substantially. This optional table provides an automated solution for volume printing of small board sizes–up to four boards can be printed in parallel on the Anapurna H2050i LED and up to five boards on the Anapurna H2500i LED. The borderless printing feature makes post-finishing superfluous.

Flawless media handling

Media loading is smooth and accurate thanks to automated features such as the media registration bar and head height adjustment. The automatically controlled vacuum system, consisting of four zones, delivers an equal vacuum during the printing process, whether printing rolls or rigid materials. This ensures flawless media transport, giving accurate print results at all times.

Ink monitoring

During production the ink levels are monitored by the automatic ink refill system. The ink (re)filling system can be accessed easily, enabling a spotless refill of your ink containers. The white ink is managed by a fully separate system (circulation, under-pressure regulation and cleaning circuit). The tank containing it is equipped with a stirring mechanism to keep the ink properly mixed at all times.

Inflatable airshaft

In the roll-to-roll mode, inflatable airshafts both on the unwinding and rewinding side, as well as a media tension roller on the rewinding side, assure perfect tension of the materials and wrinkle-free printing. While these features are standard on the largest models, they come as options on the Anapurna H1650i LED, replacing the default combination of the metal unwinding shaft with media free fall.

Extended media tables

The Anapurna H2050i LED, the Anapurna H2500i LED and the Anapurna H3200i LED come standard with an additional set of large media tables that are coupled to the default smaller rigid media tables. This makes it possible to print on rigids up to a length of 3.2 m. With the entry-level Anapurna H1650i LED, these additional large media tables are optional.

Related Products

More features

- Reinforced beam for accurate dot placement

- Automated media positioning bar mounted on table for the registration of rigids

- Shuttle safety sensors to prevent print heads from touching the substrate

- Ionization bar mounted on each side of the carriage to remove electro-static charges on the substrate

- Powerful fastscan motor

- Straightforward graphic user interface in a swivel-arm mounted touchscreen

- Convenient user interface

- Internal bitmap server with a HD of 1 TB for ripped images for fast spooling and secure transfer of big amounts of data

- Network and USB3 (2) connection

应用

- Banners, posters, exhibition graphics, POP, mock-ups, backlit, frontlit, self-adhesives (labels)

- Niche applications: wood, art reproductions, personalized object printing…

- Party gadgets (beer coasters…)

- Architectural and interior decoration, ceramics printing

技术规格

Media & Printing Specifications |

|

Rigid media |

|

| Maximum width | 165 cm (5.4 ft)

160 cm (5.2 ft) with borderless printing |

| Maximum length | 3.2 m (10.5 ft) – 4 rigid tables (2 rear & 2 front) |

| Minimum size | A2 landscape (60 x 42 cm – 1.97 x 1.4 ft) |

| Thickness | Minimum thickness: 1 mm (0.04”)

Maximum thickness: 45 mm (1.77”) |

| Maximum weight | 10 kg/m² on printing table (22 lb) |

Flexible media |

|

| Maximum width | 165 cm (5.4 ft) |

| Maximum length | n/a – restricted by weight and diameter |

| Thickness | Min. 0.2 mm |

| Maximum weight | 50 kg (110 lb) |

| Maximum roll outside diameter | Support for 3” core-media rolls with maximum outside diameter 36 cm (14.17”) |

| Borderless printing flexible media | 160 cm (5.2 ft) |

Productivity |

|

| Draft mode

Express mode Production mode Standard quality mode High-quality mode |

Up to 63 m²/h (up to 678 ft²/h)

44-54 m²/h (474-581 ft²/h) Up to 28 m²/h (301 ft²/h) 13-17 m²/h (140-183 ft²/h) Up to 7 m²/h (75 ft²/h) |

Print Heads & Inks |

|

| Print heads |

|

| Inks | Or CMYK + white

Or CMYKLcLm |

Image & Text Quality |

|

| High-quality prints | Up to 720 x 1400 dpi |

| Text quality | Positive: 4 point / Negative: 6 point |

Engine Weight & Dimensions |

|

| Printer dimensions (H x W x L) | 166 x 391 x 147 cm |

| Weight | 1,020 kg (2249 lb) |

Electricity & Compressed Air |

|

| Electricity | 380 V 3-phase star connection with Neutral wire

(3x 32A*) 50/60Hz 230V 3-phase delta connection without Neutral wire (3x 32A*) 50/60 Hz |

| Compressed air | Oil free (class 1 according to ISO 8573-1 2010), 160 l/min compressor with 50 l barrel @6bar |

| System Integration RIP / Workflow Software | Integrated production solution with Asanti, third-party RIP integration possible |

Media & Printing Specifications |

|

Rigid media |

|

| Maximum width | 205 cm (6.7 ft)

200 cm (6.6 ft) with borderless printing |

| Maximum length | 3.2 m (10.5 ft) – 4 rigid tables (2 rear & 2 front) |

| Minimum size | A2 landscape (60 x 42 cm – 1.97 x 1.4 ft) |

| Thickness | Minimum thickness: 1 mm (0.04”)

Maximum thickness: 45 mm (1.77”) |

| Maximum weight | 10 kg/m² on printing table (22 lb) |

Flexible media |

|

| Maximum width | 205 cm (6.7 ft) |

| Maximum length | n/a – restricted by weight and diameter |

| Thickness | Min. 0.2 mm |

| Maximum weight | 50 kg (110 lb) |

| Maximum roll outside diameter | Support for 3” core-media rolls with maximum outside diameter 36 cm (14.17”) |

| Borderless printing flexible media | 200 (6.6 ft) |

Productivity |

|

| Draft mode

Express mode Production mode Standard quality mode High-quality mode |

Up to 104 m²/h (up to 1,119 ft²/h)

64-71 64 m²/h (689-764 ft²/h) 32-52 m²/h (344-560 ft²/h) 19-28 m²/h (204-301 ft²/h) 14-15 m²/h (151-161 ft²/h) |

Print Heads & Inks |

|

| Print heads |

|

| Inks | CMYKLcLm + white |

Image & Text Quality |

|

| High-quality prints | Up to 720 x 1400 dpi |

| Text quality | Positive: 4 point / Negative: 6 point |

Engine Weight & Dimensions |

|

| Printer dimensions (H x W x L) | 177 x 450* x 160 cm (70 x 177* x 63″)

* without swivel arm |

| Weight | 1,800 kg (3968 lb) |

Electricity & Compressed Air |

|

| Electricity | 380 V 3-phase star connection with Neutral wire

(3x 32A*) 50/60Hz 230V 3-phase delta connection without Neutral wire (3x 32A*) 50/60 Hz |

| Compressed air | Oil free (class 1 according to ISO 8573-1 2010), 160 l/min compressor with 50 l barrel @6bar |

| System Integration RIP / Workflow Software | Integrated production solution with Asanti, third-party RIP integration possible |

Media & Printing Specifications |

|

Rigid media |

|

| Maximum width | 250 cm (8.2 ft)

247 cm (8.1 ft) with borderless printing |

| Maximum length | Supported by 1 rigid roller table: 140 cm (4.59 ft)

Supported by 1 rigid roller table + media extension table (default): 320 cm (10.5 ft) |

| Minimum size | A2 landscape (60 x 42 cm – 1.97 x 1.4 ft) |

| Thickness | Minimum thickness: 1 mm (0.04”)

Maximum thickness: 45 mm (1.77”) |

| Maximum weight | 10 kg/m² on printing table (22 lb) |

Flexible media |

|

| Maximum width | 250 cm (8.2 ft) |

| Maximum length | n/a – restricted by weight and diameter |

| Thickness | Min. 0.2 mm |

| Maximum weight | 50 kg (110 lb) |

| Maximum roll outside diameter | Support for 3” core-media rolls with maximum outside diameter 36 cm (14.17”) |

| Borderless printing flexible media | 247 cm (8.1 ft) |

Productivity |

|

| Draft mode

Express mode Production mode Standard quality mode High-quality mode |

Up to 115 m²/h (up to 1,238 ft²/h)

70-78 m²/h (753-840 ft²/h) 35-57 m²/h (377-614 ft²/h) 21-31 m²/h (226-334 ft²/h) 16-17 m²/h (172-183 ft²/h) |

Print Heads & Inks |

|

| Print heads |

|

| Inks | CMYKLcLm + white |

Image & Text Quality |

|

| High-quality prints | Up to 720 x 1400 dpi |

| Text quality | Positive: 4 point / Negative: 6 point |

Engine Weight & Dimensions |

|

| Printer dimensions (H x W x L) | 177 x 500* x 160 cm (70 x 197* x 63″) * without swivel arm |

| Weight | 2,200 kg (4850 lb) |

Electricity & Compressed Air |

|

| Electricity | 380 V 3-phase star connection with Neutral wire

(3x 32A*) 50/60Hz 230V 3-phase delta connection without Neutral wire (3x 32A*) 50/60 Hz |

| Compressed air | Oil free (class 1 according to ISO 8573-1 2010), 160 l/min compressor with 50 l barrel @6bar |

| System Integration RIP / Workflow Software | Integrated production solution with Asanti, third-party RIP integration possible |

Media & Printing Specifications |

|

Rigid media |

|

| Maximum width | 320 cm (10.5 ft)

316 cm (10.3 ft) with borderless printing |

| Maximum length | Supported by 1 rigid roller table: 140 cm (4.59 ft)

Supported by 1 rigid roller table + media extension table (default): 320 cm (10.5 ft) |

| Minimum size | A2 landscape (60 x 42 cm – 1.97 x 1.4 ft) |

| Thickness | Minimum thickness: 1 mm (0.04”)

Maximum thickness: 45 mm (1.77”) |

| Maximum weight | 10 kg/m² on printing table (22 lb) |

Flexible media |

|

| Maximum width | 320 cm (10.5 ft) |

| Maximum length | n/a – restricted by weight and diameter |

| Thickness | Min. 0.2 mm |

| Maximum weight | 0.31kg (0.682 lb) per cm (0.4”) roll width, meaning 100kg (220 lb) evenly distributed over the full 3.2 m (10.5 ft) width |

| Maximum roll outside diameter | Support for 3” core-media rolls – maximum media roll diameter 30 cm (11.8”) (larger diameter up to 50 cm (19.7”) can be allowed within the distributed weight limitation, in case only print side OUT is used – both unwinder and winder) |

| Borderless printing flexible media | 316 cm (10.3 ft) |

Productivity |

|

| Draft mode

Express mode Production mode Standard quality mode High-quality mode |

Up to 129 m²/h (up to 1,388 ft²/h)

77-87 m²/h (829-936 ft²/h) 39-64 m²/h (420-689 ft²/h) 23-34 m²/h (248-366 ft²/h) 9-19 m²/h (97-205 ft²/h) |

Print Heads & Inks |

|

| Print heads |

|

| Inks | CMYKLcLm + white |

Image & Text Quality |

|

| High-quality prints | Up to 720 x 1400 dpi |

| Text quality | Positive: 4 point / Negative: 6 point |

Engine Weight & Dimensions |

|

| Printer dimensions (H x W x L) | 177 x 572 x 193 cm (70 x 225 x 76”) |

| Weight | 2,800 kg (6170 lb) |

Electricity & Compressed Air |

|

| Electricity | 380 V 3-phase star connection with Neutral wire

(3x 32A*) 50/60Hz 230V 3-phase delta connection without Neutral wire (3x 32A*) 50/60 Hz |

| Compressed air | Oil free (class 1 according to ISO 8573-1 2010), 160 l/min compressor with 50 l barrel @6bar |

| System Integration RIP / Workflow Software | Integrated production solution with Asanti, third-party RIP integration possible |